Liquid Eductors

Water jet eductors also known as jet pumps, utilize the kinetic energy of one liquid to cause the flow of another. Eductors operate on the basic principles of flow dynamics. This involves taking a high pressure motive stream and accelerating it through a tapered nozzle to increase the velocity of the fluid (gas or liquid) that is put through the nozzle. This fluid is then carried on through a secondary chamber where the friction between the molecules of it and a secondary fluid (generally referred to as the suction fluid) causes this fluid to be pumped. These fluids are intimately mixed together and discharged from the eductor.

Water jet eductors also known as jet pumps, utilize the kinetic energy of one liquid to cause the flow of another. Eductors operate on the basic principles of flow dynamics. This involves taking a high pressure motive stream and accelerating it through a tapered nozzle to increase the velocity of the fluid (gas or liquid) that is put through the nozzle. This fluid is then carried on through a secondary chamber where the friction between the molecules of it and a secondary fluid (generally referred to as the suction fluid) causes this fluid to be pumped. These fluids are intimately mixed together and discharged from the eductor.

Eductors Specifications

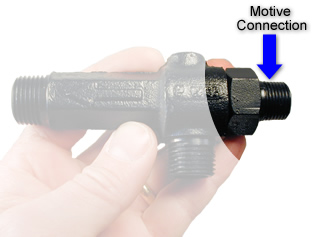

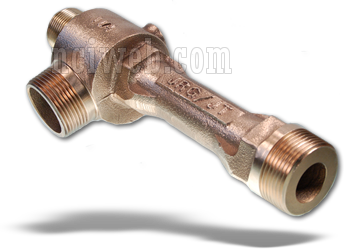

There are three connections common to all venturi eductors.

- Performance Table

- Motive Connection

- Suction Connection

- Discharge Connection

| Description | Model SL | Model ML | Model HL | Model SG | Model HG |

|---|---|---|---|---|---|

| Motive Media | Liquid | Liquid | Liquid | Steam | Steam |

| Motive Pressure (PSIG) | 15-250 | 15-250 | 15-250 | 30-150 | 20-150 |

| Pressure Recovery % | 10-15 | 30-35 | 40-50 | 15-20 | 30-35 |

| Maximum Suction Lift | -27ft. | -27ft. | -27ft. | -20ft. | -20ft. |

| Minimum Required NPSH | 3ft. | 3ft. | 3ft. | 13ft. | 13ft. |

Eductor MOTIVE Connection: This connection is where the power for the eductor is generated, by increasing the velocity of the motive fluid. The eductor nozzle in this section takes advantage of the physical properties of the motive fluid. Eductors with liquid motives use a converging nozzle as liquids are not generally compressible. Eductors with gas motives utilize converging-diverging nozzles to achieve maximum benefit from the compressibility of the gas. All of our eductor nozzles for eductors have smooth flow paths. Flow paths with sudden steps or roughness on these high velocity surfaces cause jet pumps to operate less efficiently.

Eductor MOTIVE Connection: This connection is where the power for the eductor is generated, by increasing the velocity of the motive fluid. The eductor nozzle in this section takes advantage of the physical properties of the motive fluid. Eductors with liquid motives use a converging nozzle as liquids are not generally compressible. Eductors with gas motives utilize converging-diverging nozzles to achieve maximum benefit from the compressibility of the gas. All of our eductor nozzles for eductors have smooth flow paths. Flow paths with sudden steps or roughness on these high velocity surfaces cause jet pumps to operate less efficiently.  SUCTION Connection: This connection of the eductor is where the pumping action of the eductor takes place. The motive fluid passes through the suction chamber, entraining the suction fluid as it passes. The friction between the fluids causes the chamber to be evacuated. This allows pressure in the suction vessel to push additional fluid into the suction connection of the jet pump. The high velocity of the motive stream in this section of the eductor directs the combined fluids toward the outlet section of the eductor.

SUCTION Connection: This connection of the eductor is where the pumping action of the eductor takes place. The motive fluid passes through the suction chamber, entraining the suction fluid as it passes. The friction between the fluids causes the chamber to be evacuated. This allows pressure in the suction vessel to push additional fluid into the suction connection of the jet pump. The high velocity of the motive stream in this section of the eductor directs the combined fluids toward the outlet section of the eductor. Discharge Connection: As the motive fluid entrains the suction fluid, part of the kinetic energy of the motive fluid is imparted to the suction fluid. This allows the resulting mixture to discharge at an intermediate pressure. The percentage of the motive pressure that can be recovered is dependent upon the ratio of motive flow to suction flow and the amount of suction pressure pulled on the suction port. The mixture then passes through the diverging taper that converts the kinetic energy back to pressure. The combined fluid then leaves the outlet.

Discharge Connection: As the motive fluid entrains the suction fluid, part of the kinetic energy of the motive fluid is imparted to the suction fluid. This allows the resulting mixture to discharge at an intermediate pressure. The percentage of the motive pressure that can be recovered is dependent upon the ratio of motive flow to suction flow and the amount of suction pressure pulled on the suction port. The mixture then passes through the diverging taper that converts the kinetic energy back to pressure. The combined fluid then leaves the outlet. Typical Applications

Typical Applications

Draining flooded areas, de-watering sand and coal barges, continuous blending, acidifying, causticizing of oils, pumping food products.

The Process of Sizing an Eductor

Sizing an eductor is a relatively straight forward process. The following information will help you begin the process. If you wish to have us size an eductor(s) for your application please use one of the "Request Pricing" forms to contact us.

Step 2 Divide the desired time to evacuate the volume by the number ofFt3 to be evacuated.

Desired evacuation Time/Ft3 to be Evacuated = Desired Time per Ft3

Step 3 Locate the value equal to or less than the available flowing pressure for your system in the Motive Pressure (Pm) column. If your available system motive pressure is between the listed pressures, you may interpolate between them. Choosing a lower pressure will yield a more conservative estimate. read more ...

Liquid pumping liquids performance tables.

World Class Distribution Speeds Delivery of Our Eductors

Total customer satisfaction comes from the combination of quality products purchased at a reasonable price and delivery quickly and when promised.