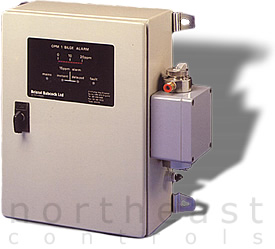

Bristol Babcock Oil In Water

Alarms

|

|

The

OPM 1 oil content alarm was specifically designed for the

control of 15 ppm marine bilge oil separators  and

fully conforms to the requirements of IMO Resolution A393(X),

and MEPC 60/33. and

fully conforms to the requirements of IMO Resolution A393(X),

and MEPC 60/33.

The design results from extensive experience in the development

of oil content meters and makes use of advanced techniques

and components. The actual concentration is displayed on a

multi element LED bargraph display and facilities are provided

for a remote recorder and alarm indication.

|

|

Operating

Technique & Facilities

|

|

The

sample flows through a cylindrical glass cell through which

a low intensity beam of infrared radiation is projected.

Two silicon photodetectors are provided to detect and scattered

path of radiation by the oil particles. The angles and

field of view of the detectors have been carefully selected

to provide high sensitivity to oil and very low sensitivity

to solids which may be present in the sample. This,

coupled with the wavelength of light chosen, ensures minimal

sensitivity to water colour and other soluble components,

and is inherently self compensating for window fouling, mains

voltage variation, and changes in ambient or sample temperatures.

|

|

|

|

Indication

and Alarm

|

|

Indication

of oil concentration is provided by the 10 element bargraph

display which provides accurate indication for a range of 20

ppm. Two alarm relays are provided, both factory set to

operate at 15ppm. One is arranged to operate immediately

the 15 ppm level is exceeded, while the other is provided with

a delayed reaction. The operating state of each relay

is indicated by solid state indicators on the door of the instrument.

Additional and similar indication is also provided for Mains

On and Equipment Fault.

|

|

|

|

Installation

And Maintenance

|

|

This

unit should be installed as close as practicable to the sampling

point. Access is only required to the top of the cell

housing, and front of the instrument. The connection

requirements should closely follow the installation diagram.

Little maintenance is required and is confined to a periodic

check of zero against clean water and occasional cleaning of

the glass sample cell, which is mounted in a cell box fixed

to the side of the main instrument case. Access to the

inside of the cell is provided by a hand-tightened screw cap,

which enables insertion of a tube cleaning brush. No dismantling

is involved.

|

|

|

|

Specifications

|

|

Range

|

0

-20 ppm

|

|

Accuracy

|

Within

IMO limits

|

|

Indication

|

10

element LED bargraph display

|

|

Enclosure

Rating

|

IP

55

|

|

Size

|

400mm

high x 380mm wide x 150mm deep

|

|

Weight

|

11

kg

|

|

Output

Signal

|

0

- 2 V DC linear for 0 - 20 ppm (minimum load 1 k)

|

|

Ambient

Temperature

|

-

15º C to +60º C

|

|

Clean

Water Requirement

|

2

bar to 8 bar

|

|

Electrical

Supply

|

220V

AC ± 10%, 50/60 Hz ± 10%

110V AC ± 10%, 50/60 Hz ± 10%

|

|

Power

Consumption

|

20

VA

|

|

Relays

|

2

off instantaneous and delayed (factory delay set @ 20 sec)

|

|

Contacts

|

Single

pole c/o Rating: 2.5A at 250 V AC

|

|

Alarm

/Fault Indication

|

3

off Instant / Delay / Fault Red LED's on front panel

|

|

Sample

Pressure

|

2

bar to 8 bar

|

|

Sample

Flow

|

1.0

litres/ min

|

|

Sample

Temperature

|

+2º

C to + 40º C

|

|

Sample

Connections

|

Compression

fitting for 10mm outside diameter pipe

|

|

|

|

|

|

|