Eductors for Heating Liquids

Eductor liquid heaters operate by condensing steam into the liquid that is being heated. The process ensures a complete transfer of the BTUs in the steam to the liquid. The steam gives up its BTUs as it condenses into the liquid. This also dilutes the motive liquid with the condensate. Eductor liquid heaters function under the normal principles of eductors. In actuality, the process is that of a liquid pumping a gas.

Eductor liquid heaters operate by condensing steam into the liquid that is being heated. The process ensures a complete transfer of the BTUs in the steam to the liquid. The steam gives up its BTUs as it condenses into the liquid. This also dilutes the motive liquid with the condensate. Eductor liquid heaters function under the normal principles of eductors. In actuality, the process is that of a liquid pumping a gas.

To better understand liquids pumping gases, refer to Jacoby-Tarbox eductor Technical Guide 700-310. The only thing that differs with pumping steam as a suction fluid is the increased affinity of steam for cold water. Because of this affinity, a greater volume of steam is pumped under the same conditions. Also, in some cases, the BTUs being released allow the unit to discharge to higher pressures than either the motive or the suction pressure.

Eductors Specifications

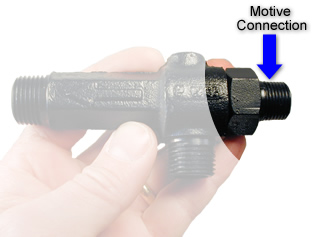

There are three connections common to all venturi eductors.

- Performance Table

- Motive Connection

- Suction Connection

- Discharge Connection

| Performance Table | |||

|---|---|---|---|

| Model | MLE | MLH | ULJ |

| Heating Process | In-line | In-line | In-line |

| Max Temp Rise (°F) | 180 | 215 | 200 |

| Maximum Flow Heated (GPM) | 5000 | 5000 | 700 |

| Steam Press Range (PSIG) | Vac-45 | Vac-120 | 0-150 |

Eductor MOTIVE Connection: This connection is where the power for the eductor is generated, by increasing the velocity of the motive fluid. The Jacoby-Tarbox eductor nozzle in this section takes advantage of the physical properties of the motive fluid. Eductors with liquid motives use a converging nozzle as liquids are not generally compressible. Eductors with gas motives utilize converging-diverging nozzles to achieve maximum benefit from the compressibility of the gas. All Jacoby-Tarbox eductor nozzles for eductors have smooth flow paths. Flow paths with sudden steps or roughness on these high velocity surfaces cause jet pumps to operate less efficiently.

Eductor MOTIVE Connection: This connection is where the power for the eductor is generated, by increasing the velocity of the motive fluid. The Jacoby-Tarbox eductor nozzle in this section takes advantage of the physical properties of the motive fluid. Eductors with liquid motives use a converging nozzle as liquids are not generally compressible. Eductors with gas motives utilize converging-diverging nozzles to achieve maximum benefit from the compressibility of the gas. All Jacoby-Tarbox eductor nozzles for eductors have smooth flow paths. Flow paths with sudden steps or roughness on these high velocity surfaces cause jet pumps to operate less efficiently. SUCTION Connection: This connection of the eductor is where the pumping action of the eductor takes place. The motive fluid passes through the suction chamber, entraining the suction fluid as it passes. The friction between the fluids causes the chamber to be evacuated. This allows pressure in the suction vessel to push additional fluid into the suction connection of the jet pump. The high velocity of the motive stream in this section of the eductor directs the combined fluids toward the outlet section of the eductor.

SUCTION Connection: This connection of the eductor is where the pumping action of the eductor takes place. The motive fluid passes through the suction chamber, entraining the suction fluid as it passes. The friction between the fluids causes the chamber to be evacuated. This allows pressure in the suction vessel to push additional fluid into the suction connection of the jet pump. The high velocity of the motive stream in this section of the eductor directs the combined fluids toward the outlet section of the eductor. Discharge Connection: As the motive fluid entrains the suction fluid, part of the kinetic energy of the motive fluid is imparted to the suction fluid. This allows the resulting mixture to discharge at an intermediate pressure. The percentage of the motive pressure that can be recovered is dependent upon the ratio of motive flow to suction flow and the amount of suction pressure pulled on the suction port. The mixture then passes through the diverging taper that converts the kinetic energy back to pressure. The combined fluid then leaves the outlet.

Discharge Connection: As the motive fluid entrains the suction fluid, part of the kinetic energy of the motive fluid is imparted to the suction fluid. This allows the resulting mixture to discharge at an intermediate pressure. The percentage of the motive pressure that can be recovered is dependent upon the ratio of motive flow to suction flow and the amount of suction pressure pulled on the suction port. The mixture then passes through the diverging taper that converts the kinetic energy back to pressure. The combined fluid then leaves the outlet.