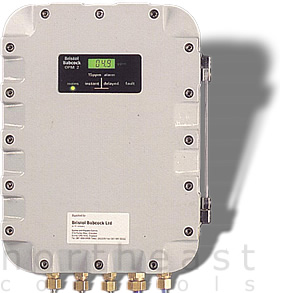

Babcock Oil In Water Alarm

- OPM 2

|

|

The

OPM 2 Oil Content Alarm has been specifically designed for

the monitoring of effluent in hazardous  areas.

At present there is no formal international specification

for 'industrial' effluent monitors. For offshore application

the OPM 2 is fully compliant with IMO specification A393X

and MEPC60(33). areas.

At present there is no formal international specification

for 'industrial' effluent monitors. For offshore application

the OPM 2 is fully compliant with IMO specification A393X

and MEPC60(33).

The design of the OPM2 Oil in Water

Monitor is the result of more than 25 years experience

in the development of

oil

content monitors, making use of advanced techniques and very

high specification components. The very low level

of concentration in parts per million of oil in water

is displayed

on a back lit LCD digital indicator. Facilities are

provided for remote indication, recording, and alarm status.

|

| Principle

of Measurement |

| Features |

| Compact |

| Continuous

Operation |

| Simple

Installation |

| Low

Maintenance Cost |

| No

Warm Up Period |

| Factory

Calibration |

| Construction |

|

The OPM2 (Option

1) is housed in a die-cast aluminum case providing protection

to IP65 requirements, and is certified for use in Zone 1 and

Zone 2 areas. The measuring cell is housed in a die-cast

aluminum case providing Explosion Proof Protection.

A further option is the OPM2 (Option 2) which allows the

control unit to be mounted in a safe area. The OPM2

(Option 2) which allows the control unit to be mounted in

a safe area. The OPM2 (Option 2) control unit is housed

in a deep drawn steel case providing protection to IP55.

The monitor and cell can be mounted independently of each

other. Interconnection is by intrinsically certified

cable.

|

| Operating

Technique |

|

The side stream sample

flows through the cylindrical glass cell, through which a

low intensity beam of infrared radiation is projected.

Two silicon photodetectors are provided to detect the direct

path of radiation, and radiation scattered by oil particles.

The angles and fields of view of the detectors have been carefully

selected to provide high sensitivity to oil and very low sensitivity

to solids which may be present in the sample stream.

This, coupled with the wavelength of light chosen, ensures

minimal sensitivity to water color, and other soluble components,

and is inherently self compensating for window fouling, mains

voltage variation, and changes in ambient or sample temperatures.

|

| Calibration |

|

The unit construction

allows factory calibration, and interchange of detector assemblies

and electronic units can then be carried out on site without

further calibration being required. The design utilises

all solid state components.

|

| Installation |

|

Installation of the

unit must in accordance with codes of practice for the country

of installation. In the United Kingdom the flameproof

code of practice is BS5345 parts 1 and 3. Bristol Babcock

Ltd recommended that in absence of a local code the United

Kingdom code of practice be used.

The OPM2 should be installed as close as practical to the

sampling point. Access is only required to the front

and top of the instrument, and the connection requirements

should closely follow the installation diagram.

|

| Maintenance |

| Little maintenance is

required and is confined to a periodic check of zero against

clean water, and occasional cleaning of the glass sample cell.

Access to the cell is provided via a screw cap, permitting insertion

of a tube cleaning brush. |

| Quality

Assurance |

| Bristol Babcock Ltd is

approved to BS En9001 (BS5750 Pt 1) In addition, the factory

in which this unit is manufactured holds BASEEFA licence MO102.

|

| |

|

| Area

Classification |

|

| Cell Assembly |

EEx

ia IIC T.4 |

| Control Unit |

OPM2(1)

EExd ia IIB T.6 |

| Control Unit (Option) |

OPM2(2)

Safe Area |

| Specification |

| Range |

0

- 20 ppm |

| Accuracy |

±2

ppm |

| Alarm Relay

1 |

Instant

Alarm: Factory Set To 15ppm |

| Alarm Relay

2 |

Delayed

Alarm at instant alarm level: Delay time variable 5 to 55 s

(factory set at 20 s) |

| Alarm Contacts |

Single

Pole c/o Rating 2.5A @ 240V 5.0A @ 110V |

| Alarm Indication |

Instant:

Red LED Delayed: Red LED |

| Fault Alarm |

Monitor

fault sets alarm condition |

| Fault Indication |

Red

LED |

| Concentration

Readout |

Back

Lit LCD display |

| Output Signal |

4

- 20 mA |

| Electrical

Supply: Standard |

240V ac ± 10% single

|

| |

50-60

Hz ± 10% |

| Electrical

Supply: Optional |

110V

ac ± 10% single phase |

| |

50-60Hz

± 10% |

| Power Consumption |

11

VA |

| Sample Pressure |

2

bar to 8 bar |

| Sample Flow |

1.0

litres/min |

| Sample Temp |

+2C

to +50C |

| Sample Connections |

Compression

fitting for 10mm outside diameter pipe |

| Ambient

Temp |

-15C

to +50C |

| Clean Water

Requirement |

Pressure

2 bar to 8 bar for cleaning and zero check |

| Size |

| Cell: 260mm

H x 120mm W x 80mm D |

| Control

Unit: OPM2(1) 445mm H x 345mm W x 210mm D |

| Control

Unit; OPM2(2) 400mm H x 380mm W x 150mm D |

| Weight

|

| Cell: 1Kg |

| Control

Unit: OPM2(1) 30Kg |

| Control

Unit: OPM2(2) 11Kg |

|

|