Size Steam or Gas Motive for Exhausting Gases

Using the Eductor Models SG and HG

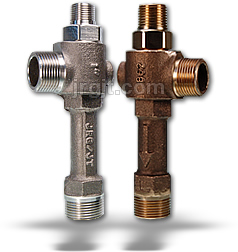

The JRG/JT models SG and HG are general purpose eductors used to pump gas with a gas as the motive stream. They can be used to pull both liquid and gas suction loads. In this case, we will deal with gas suction stream applications. The model SG is generally used with higher pressure motive flows in the ranges of 60 to 120 PSIG. It is possible to use lower pressures with these units if the outlet pressures are strictly controlled. The model HG is designed to be operated with motive pressures of 20 through 80 PSIG. Because of the increased motive flow rate in this unit, it generally will discharge against higher pressures. In general, the SG will pull a deeper vacuum on the suction connection than the model HG. If it is possible to meet the discharge conditions with the model SG, this unit is generally more efficient. Both SG and HG models can be used to evacuate, exhaust, or prime a given area. (See discussion on page 1, dealing with the difference in these applications.)

The JRG/JT models SG and HG are general purpose eductors used to pump gas with a gas as the motive stream. They can be used to pull both liquid and gas suction loads. In this case, we will deal with gas suction stream applications. The model SG is generally used with higher pressure motive flows in the ranges of 60 to 120 PSIG. It is possible to use lower pressures with these units if the outlet pressures are strictly controlled. The model HG is designed to be operated with motive pressures of 20 through 80 PSIG. Because of the increased motive flow rate in this unit, it generally will discharge against higher pressures. In general, the SG will pull a deeper vacuum on the suction connection than the model HG. If it is possible to meet the discharge conditions with the model SG, this unit is generally more efficient. Both SG and HG models can be used to evacuate, exhaust, or prime a given area. (See discussion on page 1, dealing with the difference in these applications.)

If the suction gas is not air at 70°F, refer to page 8 to convert the suction gas to Dry Air Equivalent. If the suction units are not in Lb/Hr, refer to the back cover to convert from other units to Lb/Hr. If your units are not found here, go to a conversion table in a book of chemical standards.

- Instructions on Sizing Steam or Gas Motive Eductors for Exhausting Gases

Step 1 Before beginning any application, convert all pressure and flow units into the units used in the sizing table. (If sizing is done on a regular basis with other units, request special sizing tables.) - Step 2 Find the motive pressure (Pm) column on the table that is equal to the motive pressure available at the eductor under flowing conditions.

- Step 3 Locate the desired suction pressure (Ps) from the left-hand side of the performance table. Follow this across the table until it intersects the pressure. (Pm) column selected in Step 2. This is the suction flow (Qs) of the 1-1/2" unit for model SG, HG.

- Step 4 Determine the outlet pressure (Po) of the eductor, and then determine which eductor(s) will meet these outlet conditions. If the SG will meet the outlet conditions, choose this unit to minimize motive consumption.

- Step 5 Take the desired suction flow for the eductor divided by the actual flow for a 1-1/2" unit found in Step 4. The result will be the desired S.F. for the eductor. Choose a standard eductor that has a Tabulated S.F. (page 3) that meets or exceeds the desired S.F

- Step 6 Determine the motive flow (Qm) required, by going to the performance charts. Then multiply the number found there by the S.F. of the unit selected in Step 5.

Example:

Example:

Desired Suction Flow (Qs) 17 SCFM

Desired Suction Pressure (Ps) 7 In Hg Vac

Motive Gas Media Steam

Motive Pressure (Pm) 80 PSIG

Outlet Pressure (Po) 5 PSIG

- Step 1 Convert the desired conditions into the units used in the sizing table. See the conversion factors on back cover of this manual. Convert 7 In Hg Vac to In Hg Abs: 29.92 In Hg Abs – 7 In Hg Vac = 22.92 In Hg Abs

- All other units are in the terms used in the sizing table.

- Step 2 Locate the columns for both SG and HG models with 80 PSIG motive pressure.

- Step 3 Locate desired suction pressure, (Ps) of 25 In Hg Absolute on the left-hand side of the table. Follow this line across the table until it intersects the column for 80 PSIG operating pressure. In this case, this is at a suction flow of 47 SCFM for the model SG 1-1/2" unit.

- Step 4 While determining that both models will work against the outlet pressure (Po), the model SG will require less motive resource. Choose the model SG unit.

- Step 5 Determine the Sizing Factor for the unit. 17 SCFM Desired/47 SCFM Actual = 0.362 Desired S.F.

If the desired flow is the absolute minimum flow, as in this case, choose the next larger S.F. This would be the model SG 1-1/4", with a S.F. of 0.61. If a slightly lower suction flow would be acceptable, choose the model SG 1" - Step 6 Calculate the actual performance of the unit selected. For the SG 1-1/4" unit: Steam Motive Flow = 278 Lb/Hr Steam x 0.61 = 170 Lb/Hr Suction Flow = 47 SCFM x 0.61 = 28.7 SCFM.

For the model SG 1" unit: Motive Flow = 278 Lb/Hr Steam x 0.34 = 94.5 Lb/Hr Suction Flow 47 SCFM x 0.34 = 16.0 SCFM. Choose the unit the will best meet your application conditions.