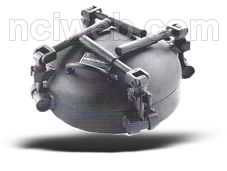

Tube Turns T-Bolt Closures

|

Tube Turns exclusive T-Bolt Closure is designed expressly for nominal pressure applications. It is less expensive and much more satisfactory than blind flanges and job fabricated closure devices. Economically priced and low initial cost are especially attractive features of the Tube Turns T-Bolt Closure. A complete unit normally costs less than the component parts for a blind or slip-on flange combination. There are no additional expenses for hinges, hoists, davits, etc., as the closure is fully assembled when shipped. Furthermore, installation-labor charges are held to a minimum; a single butt weld joins the closure to the vessel nozzle. Tube Turns exclusive T-Bolt Closure is designed expressly for nominal pressure applications. It is less expensive and much more satisfactory than blind flanges and job fabricated closure devices. Economically priced and low initial cost are especially attractive features of the Tube Turns T-Bolt Closure. A complete unit normally costs less than the component parts for a blind or slip-on flange combination. There are no additional expenses for hinges, hoists, davits, etc., as the closure is fully assembled when shipped. Furthermore, installation-labor charges are held to a minimum; a single butt weld joins the closure to the vessel nozzle.

Compact design, simplicity of construction and operation are keynotes of the Tube Turns T-Bolt Hinged Closure. The closure consists of a thick semi-ellipsoidal head that is hinged to a matching hub, a self-energizing O-ring and a suitable number of T-bolts to effect and maintain a tight seal. For most services, the standard materials - carbon steel and a "Buna-N" O-ring-are satisfactory. Other metals and elastomers are furnished on special request. The T-Bolt Hinged Closure is opened quickly and easily. The operator merely loosens the T-Bolts until they clear the holding lugs and allow the head to be swung open on its hinge. Complete, unrestricted access is provided; too, since the standard head stop permits a full 180 deg. opening.

Warning Features - The holding lugs are mounted on the closure head at an angle of approximately 10 degrees. This provides a valuable feature, for the angular mounting requires that the T-bolt be backed off an extra turn or two before it will swing out of the holding position. Thus, if there is pressure in the vessel while it is being opened, initial turns of the bolts permit the head to lift slightly and the contained fluid escapes, alerting the operator to possible danger. Further movement of the head is restrained, since the T-bolt still is confined within the holding lug. Warning Features - The holding lugs are mounted on the closure head at an angle of approximately 10 degrees. This provides a valuable feature, for the angular mounting requires that the T-bolt be backed off an extra turn or two before it will swing out of the holding position. Thus, if there is pressure in the vessel while it is being opened, initial turns of the bolts permit the head to lift slightly and the contained fluid escapes, alerting the operator to possible danger. Further movement of the head is restrained, since the T-bolt still is confined within the holding lug.

ASME Code Stamped Closures Code - stamping of Tube Turns Hinged Closures is available on request at a nominal extra cost. This includes (1) the furnishing of a Partial Data Sheet verifying shop inspection of the unit by a commissioned inspector of the National Boiler and Pressure Vessel Inspectors, and (2) the affixing of the ASME stamp on the closure.

Manufacturer's Statement of Code Compliance - In the event that shop inspection and stamping in accordance with Section VIII of the ASME Boiler and Pressure Vessel Code is not required, Tube Turns can furnish a Manufacturer's Statement of Code Compliance. This document affirms that the Hinged Closure is manufactured in accordance with the applicable requirements of the code. |

| |

Break-Over Wrench Assembly

|

|

Tube Turns offers optional attachments and accessories adding further versatility and utility of our T-Bolt Closures. Most popular of these options are the Break-Over Wrench Assembly (flip over handle) and the Camlock Assembly illustrated here. Attachment of either of these options to the closures T-Bolts provides extra convenience, speed and ease in tightening the bolts. These attachments eliminate the need for a wrench. Tube Turns offers optional attachments and accessories adding further versatility and utility of our T-Bolt Closures. Most popular of these options are the Break-Over Wrench Assembly (flip over handle) and the Camlock Assembly illustrated here. Attachment of either of these options to the closures T-Bolts provides extra convenience, speed and ease in tightening the bolts. These attachments eliminate the need for a wrench.

The Break-Over Wrenches operate similar to a wrench and requires turning by the operator to loosen or tighten the bolts whereas the Camlock Assembly is loosened or tightened by merely raising the handle.

|

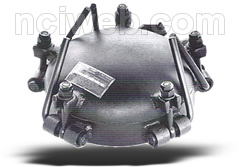

Camlock Assembly

|

|

Tube Turns offers optional attachments and accessories adding further versatility and utility of our T-Bolt Closures. Most popular of these options are the Break-Over Wrench Assembly (flip over handle) and the Camlock Assembly illustrated here. Attachment of either of these options to the closures T-Bolts provides extra convenience, speed and ease in tightening the bolts. These attachments eliminate the need for a wrench. Tube Turns offers optional attachments and accessories adding further versatility and utility of our T-Bolt Closures. Most popular of these options are the Break-Over Wrench Assembly (flip over handle) and the Camlock Assembly illustrated here. Attachment of either of these options to the closures T-Bolts provides extra convenience, speed and ease in tightening the bolts. These attachments eliminate the need for a wrench.

In a Camlock Assembly, components replace the tapped swing nut (in the hub nut mount). The Camlock bolting unit consists of a high strength eye bolt that is pinned through an eccentric cam to provide the necessary clamping action. The clamping action is adjustable by moving the adjustable nut at the threaded end of the eye bolt.

|

| Available Literature: |

| |

| {module_literature,c,88774} |

| Previous Page |

|